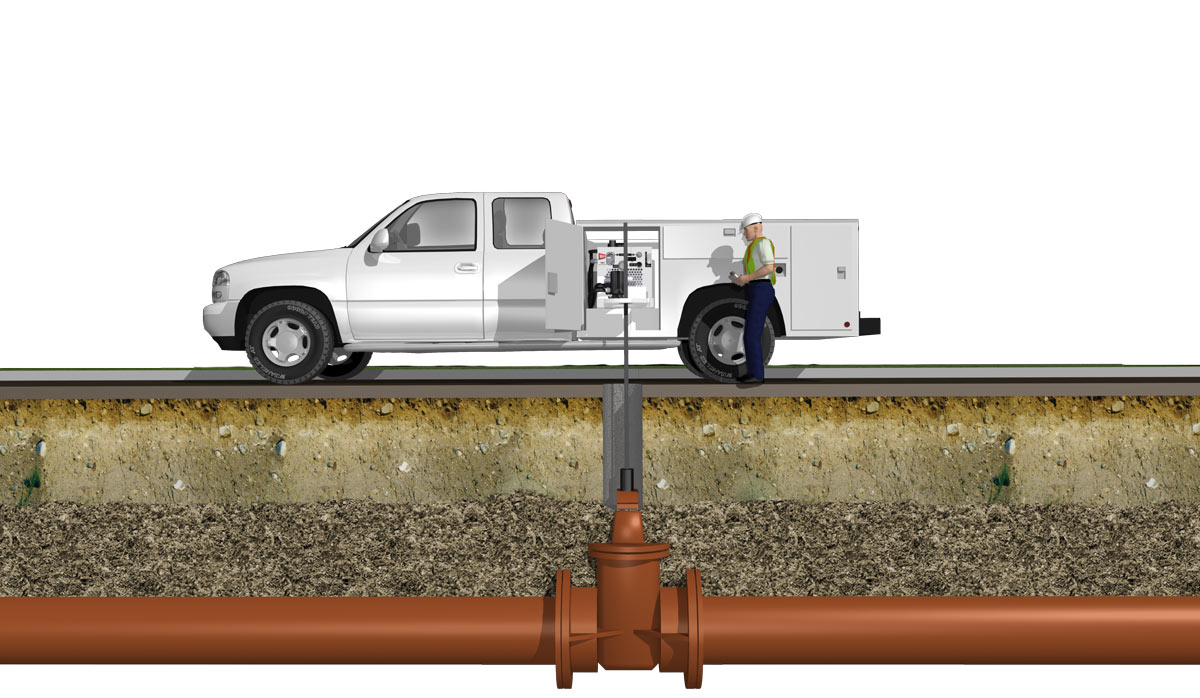

TM-7 Plus Mounted Valve Exerciser

When you need the Mack Daddy of valve exercisers, step up to Wachs TM-7 Plus. It’s designed to free and exercise the larger or older valves often found in bigger or more established cities. Difficult or impossible to operate when the need arises, simply applying brute force on these valves trying to exercise or free them up can break or damage the valve stem, leaving costly replacement as the only option. For that reason you need more than just power, you also need control and intelligence, which is exactly what the TM-7 Plus offers.

Wachs TM-7 Plus automatically conforms to the AWWA Valve Exercising Standard, allowing a single operator to exercise and rehabilitate these stubborn valves, even ones you may already have scheduled for replacement. If it’s not broken the TM-7 will likely turn it without damaging it.

Featuring a precision hydraulic drive system, the TM-7 Plus uses a onboard computer and advanced programming as its primary means for controlling torque and direction during operation; however as a backup, the Plus adds manual control of torque, direction of rotation and counts. Its design places the hydraulic motor and drive gear on a smooth, ball bearing equipped, lockable slide that offers compact dimensions with increased energy transfer.

Available as a standalone option with truck and trailer mounting options, it’s offered in two models:

17-000-33 TM-7 SD Plus Standard Duty Plus that develops up to 1500 ft-lbs (2034 Nm) of torque*

17-000-32 TM-7 HD Plus Heavy Duty Plus which develops 2500 ft-lbs (3390 Nm) of torque*

TM-7 Plus models are fully compatible with VITALS Software and come standard with Bluetooth for communication with a variety of data logging programs.

*Requires VITALS Datalogger sold separately.

HPUs and Hydraulics

16HP Gas Hydraulic Supply 17-402-00

Wachs Utility 16HP Gas Engine Driven HTMA Class II Frame Mounted Power Pack: Briggs & Stratton electric state V-Twin engine (12 kW) with hydraulic pump, capable of 8 GPS (30.3 LPM) @ 2,000 PSI (138 bar). Engine controls are operated at the front panel of the TM-7 reservoir.

Hydraulic Cooler 17-401-00 (required to add Class II Circuit)